Why Switch To Digital Control?

The building’s PRV system is the single most important component of the steam system, providing steam to every major heating system in the building. It’s too important to not have the most proven and reliable digital controls solution providing comfort to your tenants, peace of mind to building management, and savings to building ownership.

The following is a brief outline of the unique advantages Mosto Technologies digital PRV solution has brought to New York City commercial real estate market:

- Industrial rated controls solution with over 25 years of implementation in the industrial and power generation markets.

- Proven solution with over 10 years of implementation in NYC commercial market

- 181 Steam stations currently in service at 93 properties in NYC

- Successfully integrated with all major BMS protocols

- Successfully integrated with the following over 10 leading BMS/ATC providers

- Successfully Implemented custom energy reduction algorithms either through the BMS system or through our digital controller stand alone

- Fully customizable touch screen interface

- Provide M&V services to prove energy savings calculations with Mach Energy

- Documented 1 to 2 year payback

- All equipment is industrial rated

- High heat rating (up to 165F)

- Highly accurate instrumentation

- Sole source technicians who troubleshoot digital control programs, valves, system pressure components, and pneumatic systems. NO OUTSOURCING of programming

System Info

Utilize Fisher Controls and Valves

Compatible with most control valves installed (Leslie, Warren, ect) so new valves are usually not needed.

Regulators require upgrade to control valves

System Components

Main digital Controller

- Controls all system operations

- Communicates via ModBus RTU 485 or as a standalone unit

- Monitors and controls system pressures and individual valve position

- Easy Touchscreen Control

- Built in pressure safety control

Smart valve positioner

- Mounts to the valve body

- Measures exact valve position

Pressure Transmitter

- Relay exact steam pressures on the station and going out to the steam system

Provide Pressure Reducing Valves with built in noise reduction

- Reduce sound levels up to 12db

- Helps eliminate system noise issues in tenant spaces

Case Study

-

2.1 M SqFt. Commercial Office Building downtown

-

4 Pressure reducing stations throughout the building (1 per MER)

-

Utilizes steam for cooling, heating, and hot water generation

- Large commercial Con Ed steam customer in New York City wanted to lower its operational steam costs.

- Mosto Technologies recommended retrofitting all 4 of the building’s steam pressure reducing stations with digital control capability.

- By modulating low end steam pressures based on weather conditions energy savings were generated.

- Utilized current Leslie control valves

- Upgraded the controls only

- System utilizes digital control but valves still operate pneumatically.

Scope of Work

- Gather valve info and layout of each station

- Install pressure sensors on the station

- Install positioners on each pressure reducing valve

- Install digital Controller to collect data points and control the station

- Calibrate and commission systems

- Develop custom control strategies to drive energy savings based on weather conditions and building steam loads

- Connect each PRV station controller up the building’s BMS system

- Confirm, track, and develop savings analysis once the system is fully operational

Results / Savings Analysis

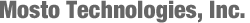

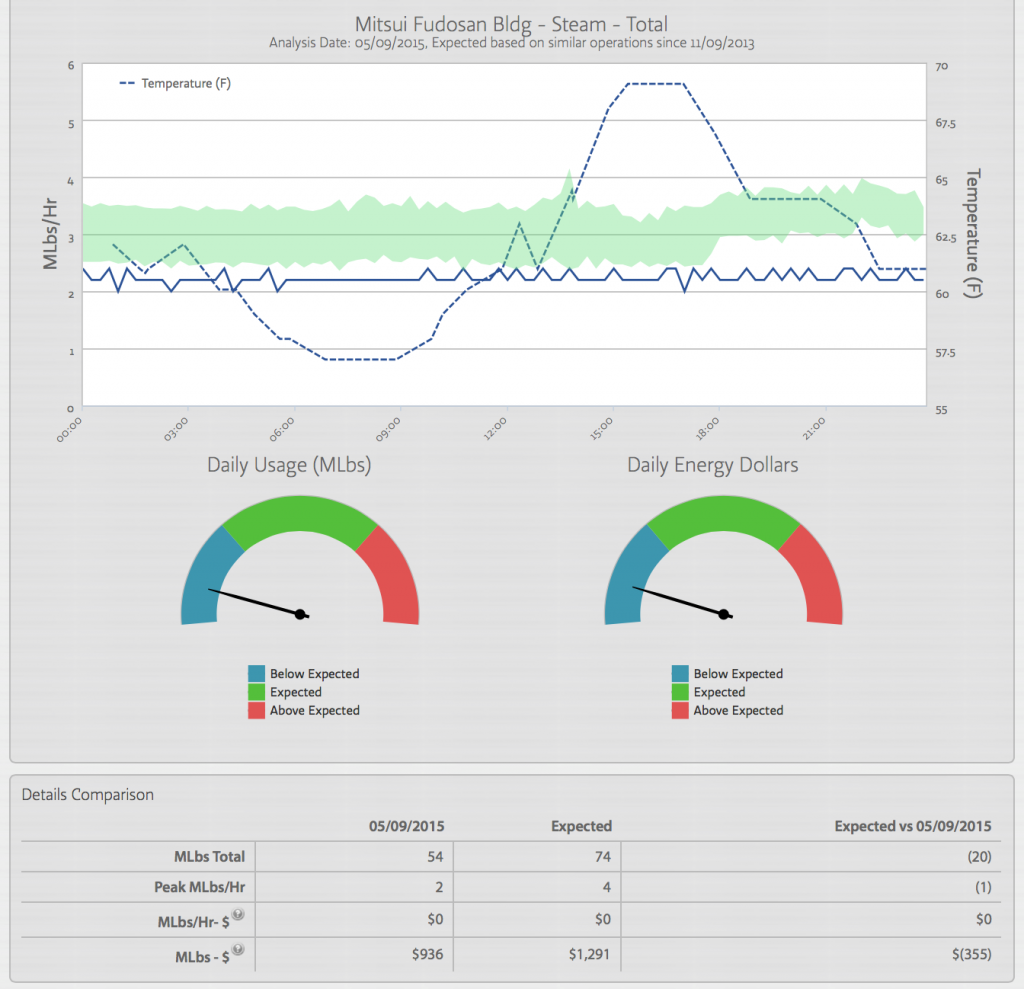

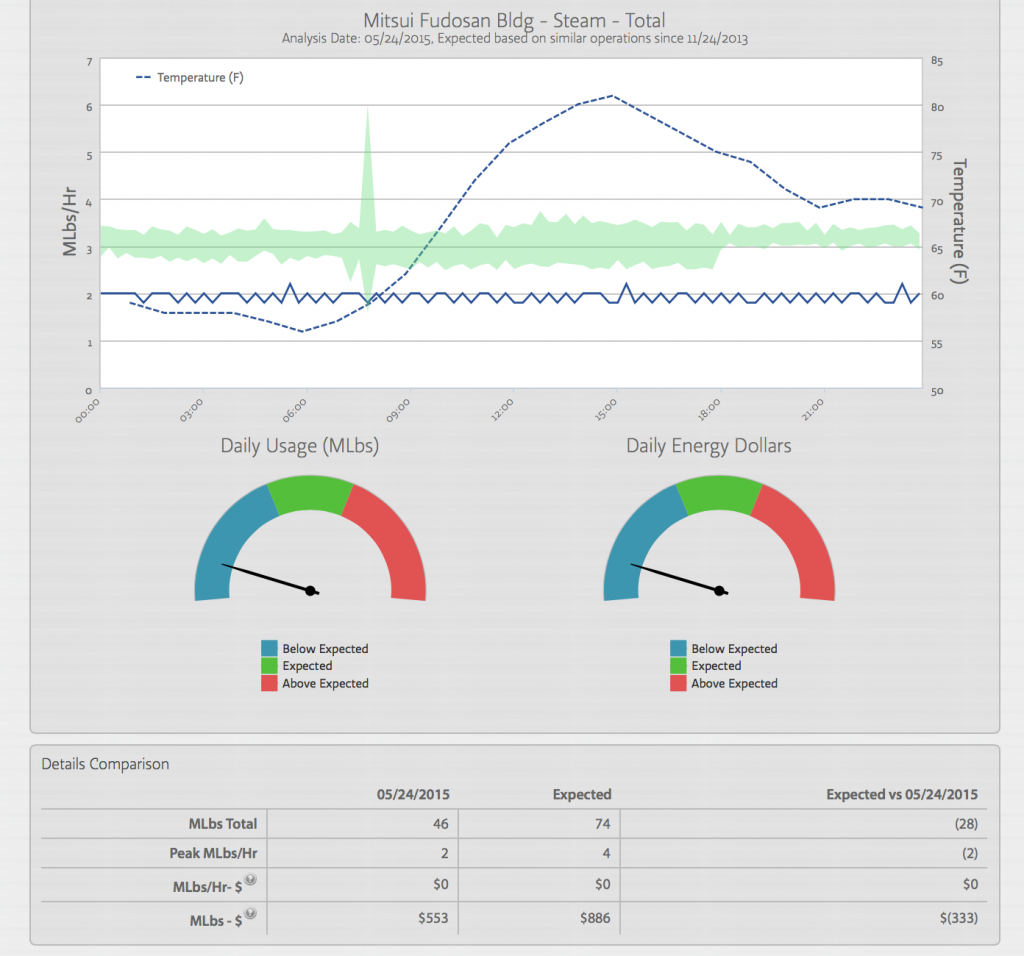

Throughout the year, the building’s steam usage was tracked and trended through an online energy monitoring platform developed and supplied by MACH Energy. Savings were derived by lowering the steam pressures based on outside air temperatures. During lower load times higher steam pressures are not needed to meet the buildings capacity needs.

- By lowering steam pressures the buildings was able to reduce its baseline consumption by an average of 500 Lbs per hour.

- That equals an average of 360 Mlbs per Month

- 360 Mlbs per Month with an average Con Ed rate of $28 per Mlbs equals $10,000 per month in savings.

- The project showed a documented payback of 1 year

The following chart shows the actual 500 Lbs per hour baseline reduction at the property.

The blue line is the previous baseline, while the orange is the new baseline. As you can see the baseline was reduced by an average of 500 Lbs per hour.

The steam usage is also much tighter with very little volatility.

This is also a key benefit to the systems digital control capability.

HP Riser Digital PRV Upgrade Case Study

Background Information

- 1 M SqFt. Commercial Office Building downtown

- High pressure steam riser feeding 160 PSI steam up 54 Floors

- Utilizes steam for cooling, heating, and hot water generation

- Large commercial Con Ed steam customer wanted to lower its operational steam costs.

- Mosto Technologies recommended installing a dedicated high flow / low flow PRV station with digital control capability on the high pressure steam riser.

- Developed custom control algorithm to take into account outside weather, and steam consumption on the upper MERs to reduce steam pressure in the riser and generate savings

Scope of Work

- Reviewed steam interval consumption data to develop valve sizing for new steam station

- Develop a basis of design for the installation of the steam station

- Install a parallel 2 valve high flow / low flow steam station in the steam room in bypass of the HP steam riser

- Mapped control points over to the BMS

- Worked with BMS provider to develop custom control algorithm

Results / Savings Analysis

Throughout the year, the building’s steam usage was tracked and trended through an online energy monitoring platform developed and supplied by MACH Energy. Savings were derived by lowering the riser steam pressure based on outside air temperature along with the top of the house steam pressure and consumption of the upper MERs.

- Pressure was reduced from 160 PSIG to between 30 and 90 PSI depending on the weather conditions.

- At no point has the riser required more than 90 PSI since the dedicated PRV station was installed.

- By lowering the riser steam pressure the building was able to reduce its consumption by an average of 500 Lbs per hour.

- Equaling an average of 340 Mlbs per Month

- 360 Mlbs per Month with an average Con Ed rate of $30 per Mlbs equals $10,800 per month in savings or $129,600 per year.

- Total project cost was $278,000

- The project showed a documented payback of 2.1 years

Metering and Verification

These pictures show the actual baseline reduction at the property. The green shaded area is the previous baseline, while the blue line is the new baseline. When comparing the before and after pictures, note that the baseline was reduced between 1000 and 400 Lbs /hr Lbs per hour at those specific times. Over the course of the year the average reduction was 500 Lbs/Hr. After the riser was upgraded the individual MER PRV stations were upgraded with digital controls. The riser steam station and the upstairs steam stations now work in conjunction with one another to maximize the building’s steam system efficiency.

Please Call 212.239.1422 or Email to schedule a walk through to discuss the system